Abstract—This paper concerns the functional principles of automotive alternator systems.

INTRODUCTION

Automotive alternator or charging systems are made up of three components: the Alternator, which is essentially an AC generator, a Voltage regulator and a 12V Battery. This paper will explore this simple system particularly as it relates to a 1982 BMW 320i Coupe.

II.

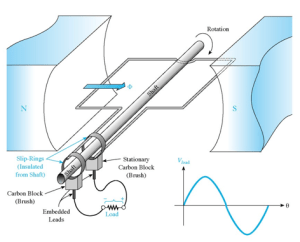

Alternators work on the principle of electromagnetism laid down in what is probably one of the top three most important concepts in electrical engineering: Faraday’s Law. Faraday’s Law states simply that when a coiled conductor is exposed to a moving magnetic field, a current is induced in the conductor. More accurately, an electromotive force is created, which induces a current in the conductor. The force produced by the movement of the magnetic field within the coil is amplified by the number of turns in the coil, signified by the variable (N). Faraday’s law is shown in figure 1.

Fig. 1, Faraday’s Law (Lenz’s Law)

This formula at its most basic level, describes the process by which mechanical energy (work) can be converted into electricity. This is exactly what an alternator does. It converts the energy output from the burning of gasoline (or diesel) into electricity to keep the car’s 12V, battery-powered electrical system topped off.

III.

Typically, an automotive alternator should output enough voltage potential to keep a 12V car battery at a voltage of approximately 14V. Testing of the charging system of the 1982 BMW 320i Coupe used as an example in this paper with a DMM reveals that the 320i’s alternator “outputs” approximately 13.5V. This is a bit low but, as stated before, an alternator converts mechanical energy to electrical energy. This BMW has a slowly failing in-tank fuel pump and a worn-out distributor bearing. It is also possible that there could be a pinhole vacuum leak somewhere in the intake manifold boot, which is a 33+ year old rubber part. All these variables add up to less than optimal engine performance, which translates to less than optimal mechanical energy output, which further translates to less than optimal alternator output. The 320i’s voltage output is displayed in figure 2.

Fig. 2, Charging output of a 1982 BMW 320i alternator

The voltage output of the 320i’s alternator increases when the throttle is opened (fuel is injected into the engine). This is consistent with how an alternator is expected to perform. Alternator current output is proportional to rotations per minute of the alternator pulley, which is controlled by the engine’s power output. The faster the car is going, the more current is produced by the alternator. This concept is exemplified by the chart in figure 3 below.

Fig. 3, Alternator Output – Amps vs Engine RPM

This is why, if a battery is flat, it can be recharged by a long (hour or more) drive. As previously stated, an alternator is designed to simply top-off battery charge but, given enough time under normal running conditions, an alternator will generate enough power to fully recharge a 12V battery.

However, this scenario is by no means ideal. An alternator is not designed for fully recharging a battery. It can simply be used to do so. Optimally, a dedicated battery charger that plugs into the main grid should be used to recharge a flat battery.

IV.

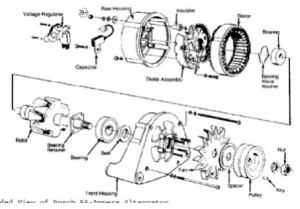

An alternator is essentially an AC generator so it consists of an armature, a magnetic pole, a commutator and a rotor shaft. An automotive alternator also features an interior cooling fan to dissipate the heat generated by spinning and producing electricity as well as a voltage regulator that distributes and controls the amount of current produced by the alternator that goes to the battery. Figure 4 is an exploded-view diagram of a Bosch alternator similar to the one on the 1982 BMW 320i used as an example in this paper.

Fig. 4, Exploded-view Diagram of Bosch Alternator

The average alternator has five terminals. An S-terminal senses the battery voltage. The IG terminal is attached to the ignition switch that turns the voltage regulator on when the engine is cranked. Under nominal operating conditions, the L terminal closes the circuit to the battery warning light. The B terminal is the main alternator current output terminal, which is attached to the positive battery terminal. Finally, the F terminal is the full-field bypass for the regulator.

Batteries need a direct current. Because alternators are actually AC generators, they are fitted with a diode rectifier (or rectifier bridge) in order to convert the current before it gets sent to the battery.

V. CONCLUSION

Alternators produce an AC current that is rectified to DC and then sent off to charge the battery. The amount of voltage put on the battery is determined by a voltage regulator fitted to the alternator generator. The regulator determines when to deliver voltage and how much voltage is needed to be delivered to the battery.

Alternators are crucial automotive component that an engine will not run on its own without a properly functioning one.

When running, a car’s alternator should deliver a DC voltage of approximately 14V to the car’s battery. If this voltage is below the 14V threshold, it may be possible that the alternator is failing. In that case, it is advisable to immediately have the part replaced to avoid power loss while driving, which can be an incredibly dangerous scenario. It is also advisable for car owners to purchase name-brand alternators from quality parts makers like Bosch. Off-brand and discount alternators use low-quality parts to keep their overhead low and as a result, the inferior parts have a low lifespan. Buying quality parts will save money in the long run.

REFERENCES

HYPERPHYSICS. Faraday’s Law. [Online]. Available: http://hyperphysics.phy-astr.gsu.edu/hbase/electric/farlaw.html

MINEBEA. History of Brushless DC Motors. [Online]. Available: http://www.nmbtc.com/brushless-dc-motors/brushless-dc-motors/

OHIO ELECTRIC MOTORS INC. Permanent Magnet DC Motors. [Online]. Available: http://www.ohioelectricmotors.com/permanent-magnet-dc-motors-649

ALL STAR MAGNETICS. Neodymium Magnets. [Online]. Available: http://allstarmagnetics.com/index.php/neodymium_magnets

Fawwaz T. Ulaby, Eric Michielssen, Umberto Raioli, “Maxwell’s Equations for Time-Varying Fields,” in Fundamentals of Applied Electromagnetics, 6th ed. Prentice Hall Publishing

Nikola Tesla, “My Later Endeavors,” in My Inventions – The Autobiography of Nikola Tesla, New York, 1919

Gordon Tobias S.A.E., “Engine and Engine Overhall,” in Chilton BMW Coupes and Sedans 1970-88 Repair Manual, 1996, Haynes North America Inc.